Proucts - Orientator quality

The guidance counselor has two high-definition digital cameras, which allow precision testing of natural corks .

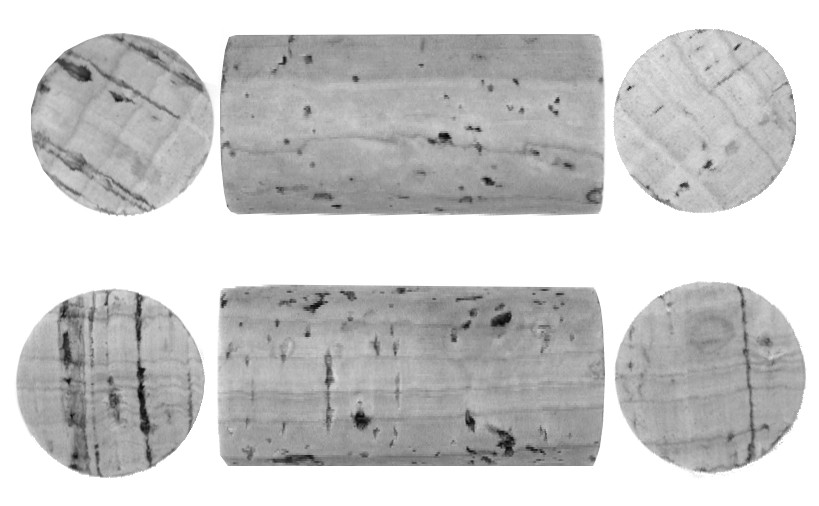

Thanks to the use of dedicated illumination, the system takes a very detailed picture of both the flat surfaces of the stoppers. A specially developed software allows the analysis of the two images to determine the head better quality, that is, according to the number and type of defects detected.

At this point, the cap is oriented according to your choice, using a mechanical device - high precision pneumatic already extensively tested by the manufacturer.

The orientation quite accurate and reliable according to the caps of the best side makes it possible to put a mark next or make a quality bevel on the bottom.

This way you can guarantee a constant quality of supply.

The analysis of the two surfaces of the cap to make a choice depending on quality, is also very interesting for the most demanding wine cellarsi. In addition to ensuring constant to insert the plugs into the bottles with the best side always in contact with the product, it is important to discard the possibility that the caps do not have sufficient quality characteristics expelling them in a separate channel.

Each station east to the productivity of 7,000 caps / hour, with a guarantee of proper operation of the analysis, comparison and subsequent positioning of the caps described above with the utmost precision. For higher production rates can be used two or more stations in parallel.

The referral system is based on the innovative and patented referral system equipped with a mechanical rotating mechanically operated rotary powerful yet delicate.

The referral mechanism operates with low noise and vibration compression avoids any of the plugs, requires no adjustments to the format change, prevents the formation of dust and debris during the handling of cork stoppers and the capper can feed up to 20 meters distance allowing the storage of plugs in a dedicated environmen.

| Photo | Catalog | Model | Corks h oriented | Corks h no oriented |

| OR.VI.8 RM 2 CAMERAS | 7.000 | 10.000 | ||

| OR.VI.16 RM.1 2 CAMERAS | 14.000 | 20.000 |

| MODELLO | OR.VI. 8 RM 2 telecamere | OR.VI. 16 – 1 RM 2 telecamere ogni stazione |

| PRODUZIONE ORARIA | 7.000 | 14.000 |

| Struttura Inox aisi.304 | Sì | Si |

| Capacità tramoggia (Lt.) | 350 | 400 |

| Altezza di carico tramoggia (cm) | 105 | 105 |

| Tramoggia fondo oscillante | Sì | Sì |

| Elevazione nastro | L.200 | L.200 |

| Convogliatore indipendente | Sì | Sì |

| Uscita convogliatore | 1 canale | 2 canali |

| Alternatore da 2 canali in 1 | No | Sì |

| Ottica monocromatica 2 telecamere | Sì | Sì |

| Software analisi qualità | Sì | Sì |

| Monitor touch-screen Lingua : Ita – Fra- Ingl – Spa |

Sì | Sì |

| Regolazione intensità illuminazione | Sì | Sì |

| Visualizzazione processi di lavoro | Sì | Sì |

| Espulsione tappi non conformi | Sì | Sì |

| Rinvio meccanico rotativo | Sì | Sì |

| Invio distanza massima: | 20 | 20 m |

| Dimensioni tappi in lavorazione standard Ø 23 mm - …. Ø 30.5 mm H 40 mm - …. H 48 mm |

||

| Consumo aria compressa (5 bar) | 20 nl’ | 40 nl’ |

| Voltaggio standard V400 – 50HZ | Si | Sì |

| Potenza installata | 850 W | 2000 W |

| Dimensioni di ingombro (cm) | 250x90 | 300x90 |

| Altezza totale (cm) | 260 | 340 |

| Peso (kg) | 350 | 500 |

| OPZIONI DISPONIBILI | OR.VI. 8 RM 2 telecamere | OR.VI. 16 – 1 RM 2 telecamere ogni stazione |

| Tramoggia 350 Lt | Inclusa | Inclusa |

| Tramoggia 800 Lt | Sì | Sì |

| Tramoggia 1.400 Lt | Sì | Sì |

| Scarico rapido della tramoggia | Sì | Sì |

| Realizzazione sino 16 programmi formato | Sì | Sì |

| Oblò ispezione testata incanalatore | Sì | Sì |

| Aspiratore polveri con o senza imp. elettrico | Sì | Sì |

| Deviatore pneumatico Alimentazione | Sì | Sì |

| Scarico pneumatico del canale alimentazione verso il tappatore | Sì | Sì |

| By-pass per alimentazione diretta al rinvio meccanico | Sì | Sì |